Smart. Sharp. Sustainable.

Innovating today for a cleaner, smarter tomorrow.

At Sharp, we believe technology should not only enrich lives—but protect the planet. That’s why sustainability is embedded in everything we do—from how we design and manufacture our products, to how we support responsible disposal and recycling at end-of-life. We’re reimagining what modern technology can achieve—for people and for the environment.

A Global Vision, A Local Commitment

While Sharp’s sustainability strategy is driven at a global level, its impacts are felt locally—including right here in New Zealand. Whether through our energy-saving technologies, recycling partnerships, or responsible sourcing, Sharp New Zealand proudly supports these global initiatives in tangible, real-world ways.

Designing for Energy Efficiency and Lower Carbon Impact

Consumer electronics play a significant role in global energy consumption—and much of their environmental impact occurs during everyday use. At Sharp, we are committed to reducing this footprint through smarter, more energy-efficient product design.

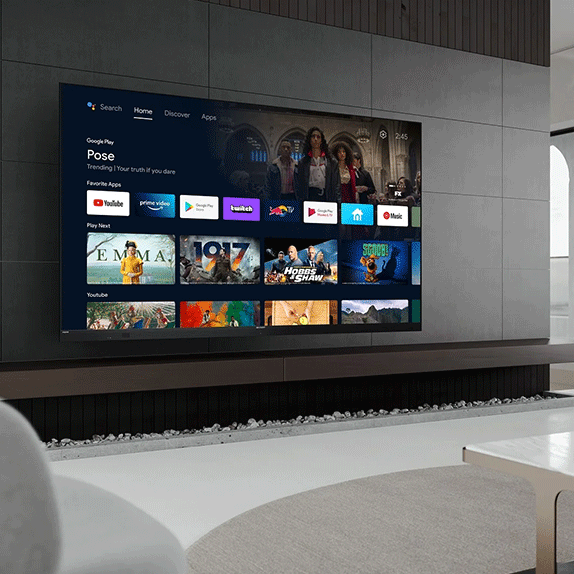

By continuously enhancing the energy performance of our products and reducing material use, we not only lower power consumption but also help reduce emissions over the entire product lifecycle. A strong example of this is our latest 8K television model. Through innovations in both energy efficiency and lightweight structural design, we were able to reduce life cycle CO₂ emissions by 18% compared to previous models.

This improvement reflects a broader effort across all Sharp product categories to address climate change at every stage—from raw material sourcing and manufacturing, through to consumer use and responsible end-of-life recycling. By making energy efficiency a core priority in product development, we’re helping consumers enjoy cutting-edge technology while shrinking their environmental footprint.

Sharp Sustainability Report 2025

Building a better world through Environmental, Social, and Governance leadership

Sharp’s 2025 Sustainability Report outlines our ongoing commitment to creating a sustainable, inclusive, and responsible future—guided by a global vision of ethical innovation and environmental stewardship. This comprehensive report showcases Sharp’s dedication to Corporate Social Responsibility (CSR) and details how we are aligning our business practices with the values and expectations of today’s society.

The report is structured into three core pillars—Environmental Initiatives, Social Initiatives, and Governance—each supported by detailed data, performance metrics, and progress updates.